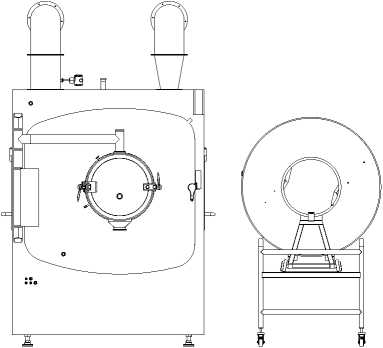

BGB-F High-efficiency Coating Machine interchangable coating pan

Application

The new type auto coating machine is designed for coating process solutions for all kinds of tablets, pills, granules, which can promote the coating production efficiency and guarantee material stability. Reliable process, interchangeable pan design, CIP design and good appearance conform to the requirements of GMP. Varieties of functions make the batch production time shorten, Satisfying different process requirements. It is the best choice for film coating, sugar coating.

Features

▲ Overall open design on the front side

▲ Easy cleaning, no dead corner

▲ Wide install area and maintenance space and pans can be replaceable

▲ Unique airbag seal structure, fully enclosed chamber

▲ It adopts HMI and PLC automatic control system, can optionally comply 21 CFR Part 11 requirements

Tippii^ lifting feeder

▲Achieving smoothly loading tablet into the coating pan

▲Prevent fragments and bracts because of the height difference colliding

▲Auto lifting and tipping, the tablets can slide into the coating pan evenly and slowly

Technical Parameter

| Item Model |

BGB-75F |

BGB-150F |

BGB-250F |

BGB-350F |

BGB-600F |

| Production capacity(kg/batch) |

75-40-20 |

150-75-40 |

250-150-75 |

350-250-150 |

600-350 |

| Main machine motor power(kW) |

1.5 |

2.2 |

3 |

4 |

5.5 |

| Drum rotation speed (rpm) |

2-24 |

2-15 |

2-15 |

2-15 |

2-10 |

| Hot air fan power(kW) |

1.1 |

1.1 |

1.5 |

2.2 |

5.5 |

| Exhaust fan power (kW) |

4 |

5.5 |

7.5 |

11 |

15 |

| Peristaltic pump power(kW) |

0.04(BT100L) |

0J(WT300F) |

0.1(WT300F) |

0.1(WT300F) |

0.1(WT600F) |

| Steam consumption(kg/h) |

95 |

95 |

169 |

225 |

252 |

| Air consumption(m3/min) |

1.18 |

1.45 |

2.03 |

2.03 |

2.57 |

Note: Our company can customize products according to user requirements

Market- Cases (International)

Production - advanced processing equipment

Production - advanced processing equipment

Production - Lean management (Assembly site)

Production- Quality management

Quality policy:

customer first, quality first, continuous improvement and excellence.

Advanced processing equipment + precision testing instruments + strict process flow + finished product inspection + customer FAT

=Zero defect of factory products

Production quality control (precision testing instruments)

packing & shipping